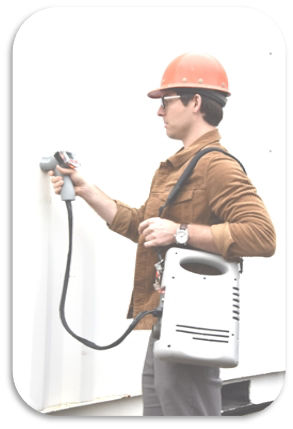

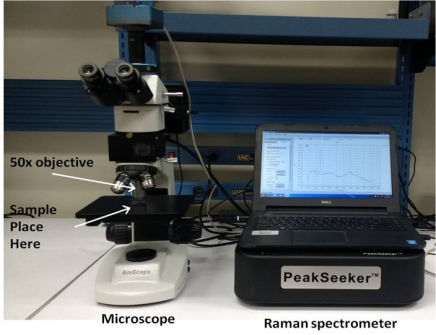

Paint Analysis Under this Rapid Innovation Fund (RIF) Program, Optowares and Boston Engineering Corporation are developing methodology, protocols, hardware, and software to produce an experimentally verified handheld hull surface condition sensor to evaluate bare steel and paint materials of interest to the US Navy to determine the condition of the surface just prior to the application of a coating or adhesive. By analyzing a hull surface and determining the surface is contaminant free and suitable for coating, this work will culminate in the substantial mitigation of delamination risk at material interfaces.